This is how it works

Leanbyte for Quality Assurance

Binding test documentation leads to quality awareness

Faulty processes or products are automatically catalogued

Every member of staff is able to carry out quality assurance measures.

Assembly line Fittings with 200 Variants

Quality assurance

Check date marking

Target time: 30 seconds

Target state: Daum is current

Inspection feature: Date marking

Number of samples: 3

Testing equipment: Visual

Measures in the event of a fault:

Inform the shift supervisor.

1

Quality assurance

Quality assurance

Check shaping

Target time: 30 seconds

Target state: Part fully formed

Inspection feature: Whole part

Number of samples: 3

Testing equipment: Visual

Measures in the event of a fault:

Inform the shift supervisor.

2

Quality assurance

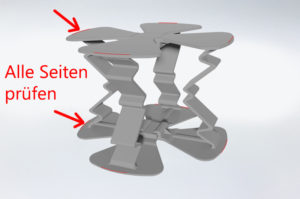

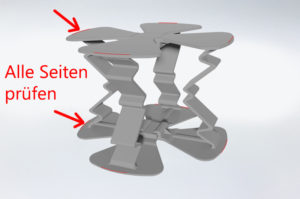

Quality assurance

Check burr formation

Target time: 30 seconds

Target state: No burr formation

Inspection feature: Whole part

Number of samples: 3

Testing equipment: Visual

Measures in the event of a fault:

Inform the shift supervisor.

3

Quality assurance